How do you solve a problem like aging?

30 years on from the commissioning of Scotland’s first commercial onshore wind farm, Scottish Renewables hosted a timely seminar focussing on the topic of repowering. The event, held in Glasgow this month, drew delegates from across the industry to discuss the reality of what to do with an aging fleet of turbines that are rapidly reaching the end of their financially useful lives.

By the end of this decade, the first tranche of utility scale wind turbines will have reached or exceeded their design life, and many will have become more expensive to maintain than the revenue they collect. By 2050, as many as 5,500 turbines in Scotland will have to be decommissioned.

To achieve the country’s 2030 target, an additional 12GW of onshore wind will be required. At the same time, it is projected to lose as much as 1GW through aging. This raises several questions; first, what to do we do with 1GW of turbine components when the Scottish government is committed to a circular economy? Secondly, what do we do with the prime wind farm sites that were selected due to their optimal wind conditions, grid connections and accessibility now that the turbines are no longer viable?

We sat down with Neil Marshall, Advisory Lead for Onshore Wind at Natural Power, who presented at the event, for his take.

Decommissioning – it is believed that between 85% and 95% of a turbine can be recycled, depending upon which original equipment manufacturer (OEM) you speak to. To do so, a supply chain specialising in the repowering, refurbishment and re-use of turbine components will have to be quickly deployed to avoid up to a million tonnes of industrial materials ending up in landfill. Steel from the turbine towers could be recycled and turbine components could be refurbished or used as training aids for colleges and universities, the greatest challenge remains in the disposal of glass fibre blades where an effective solution has yet to be developed.

As Neil suggests “A key takeaway from this event was that the industry must come together to find a solution. We want to reduce the effects of climate change and as an industry, we cannot be seen to generate millions of tonnes in industrial waste in the process. Realistically, however, if operators get more from melting down materials than reusing or refurbishing, how do we encourage them to take the circularity route which may incur more costs or lesser returns? Perhaps the answer lies in policy drivers where recycling / reusing / refurbing targets are added to decommissioning agreements or governments are more strategic in their use of tax incentives.”

The OEMs are currently exploring the issue of blade recycling by developing different resins that can be dissolved after use to release the fibres within their wind turbine blades, making them reusable. Siemens Gamesa is looking to develop fully recyclable blades in their bid to meet its goal of making its wind turbines fully recyclable by 2040. Vestas has announced a new process for separating the fibres and resin from their blades to allow circularity. Ørsted meanwhile is looking at reusing the materials from their blades to form fibre boards for walls and flooring. The ideas are there, making them an integral part of every project lifecycle and financially viable is the challenge.

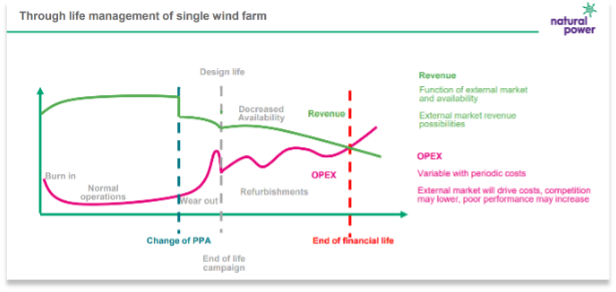

Repowering – next we look at the wind farms whose turbines are no longer viable. At what point should owners / operators start looking at next steps? There are many factors to consider. For example, when will a turbine reach the end of its profitable life, can that period be extended and what point does that OPEX become unviable? Is it better to repower, replant or decommission? Each site will present its own particular challenges and the planning involved in the next steps of development for these sites will have to be carefully considered.

The options are many, from reducing the turbine numbers per site but increasing their size, to adding complementary technology such as solar and energy storage. These questions are being repeatedly asked of Neil and his team, along with the biggest of them all; when should we start planning for the next steps in wind farm’s life? In response, Neil explains “there is no single answer to this as each site varies, from the expected energy yield should additional technologies by collocated, to the logistics of repowering or decommissioning equipment, the land agreements in place and the financial models to base future projections on. What is true, is the earlier you begin asking these questions, the better prepared you will be.” Something his team is ably placed to support on.

Planning - in Scotland, the National Planning Framework 4 (NPF4) was adopted on 13 February 2023 and now incorporates spatial planning and policy direction. Because of this, NP4 will assume a greater role in the decision being made in the planning system. The strategic spatial strategy supports electricity generation and associated grid infrastructure throughout Scotland including from repowering, helping to reduce emissions, and improving security of supply. This sends a clear message that additional electricity generation from renewable sources and repowering is considered a strategically important aim within NPF4. and, in terms of planning considerations, it lends greater weight to the policy direction supporting renewable technologies and grid resilience.

What is noticeably clear, given the number of attendees at this seminar and the number of questions being posed, is that there is a strong appetite in the industry to get this right. There is however a ticking clock, so we need to start finding solutions, and quickly.

If you have any questions regarding the next phase of your wind farm, please sayhello@naturalpower.com.

Details of the Scottish Renewables Repowering seminar can be found here: Repowering Onshore Wind Seminar (scottishrenewables.com)