Natural Power’s Inspections team offers expert support and services throughout the lifecycle of your project. As part of the quality assurance process, we can ensure that components are fit for purpose before installation by undertaking factory visits or on-site inspections. Once the assets are operational, we can conduct regular maintenance checks as part of a proactive maintenance programme and as the assets mature, we can support you with end of warranty, life extension, and health assessments.

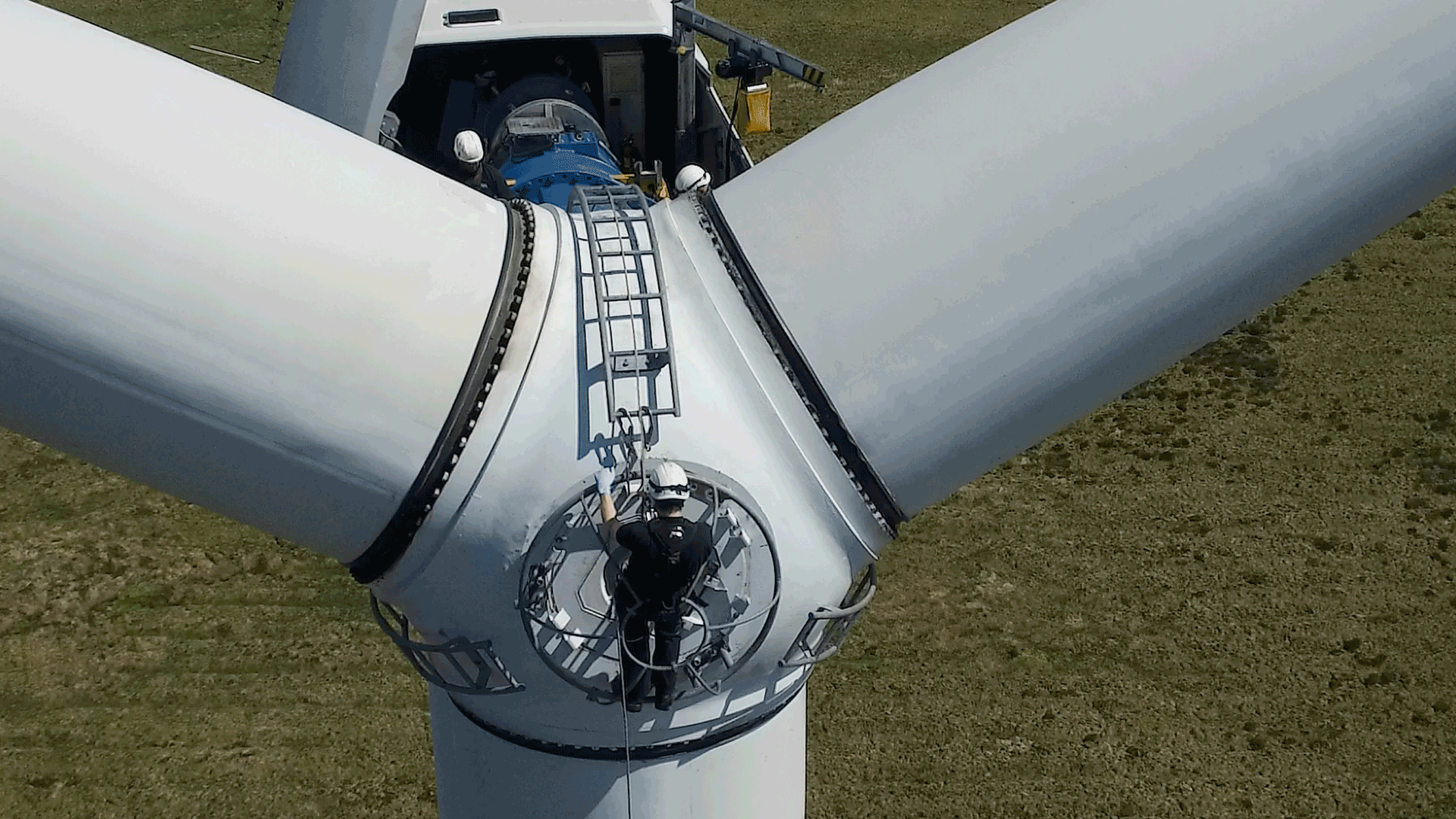

Wind turbine Inspections

We can help you to maintain a healthy wind turbine fleet that performs at its best. Our expert inspections team can assess your fleet, diagnose any problems, and predict the repairs a turbine might need and when. This results in a well-organised and cost-effective maintenance plan that suits you. Our proactive approach to wind turbine upkeep reduces downtime, and it helps provide maximum output from your turbines.

We monitor every part of your turbines and make sure they are working well and will continue to operate. We perform:

-

End of Warranty inspections

-

Life Extension assessments

-

Quality Assurance inspections

-

Endoscopy inspection

-

Internal & external blade inspections

-

Pre & Post Commissioning inspections

-

Lubrication Sampling & Analysis

-

Data analysis

We use a range of inspection methods, including data led targeted component inspections, intrusive works and detailed visual inspections. Our use of ground-based technology means that our blade inspections are fast, efficient and produce accurate, repeatable images and reports. This lets us identify and fix damage quickly, keeping your site working as economically as possible.

Solar & Battery Energy Storage Inspections

Our in-house engineers are experienced in undertaking photovoltaic & battery energy storage system (BESS) inspections, with combined projects totalling over 700MW to date. These 3rd party inspections can be completed as part of a due diligence, or our team can support on specific technical inspections following periods of operational downtime, or prior to a change of operation and maintenance contracts.

These inspections will highlight any areas that should be addressed to ensure the assets are operating at maximum capacity throughout their lifetime.

Upgrade & Retrofit Projects

Natural Power’s team collaborate with original equipment manufacturers to engineer solutions and provide installation services for retrofit and upgrade campaigns.

One of our most recent projects involved the hardware and electrical installation of auto lubrication systems. This upgrade ensures that our client will reduce maintenance costs on a yearly basis while also extending the lifetime of components.

As a team, we have years of experience completing various projects. Whether it be relating to installation of new systems within your asset, or an upgrade due to design issues, we have it covered.

For information on how our Inspections team can help you with your project, say hello to Stefan Hendren.